DIFLICOM is convinced that by avoiding “hot” work on the factory sites, the overall safety gets a positive boost. In addition, this makes a positive contribution to reducing the total costs.

To achieve this, DIFLICOM uses Quickflange™ weldless flange connections and Lokring® fittings. Both technologies meet the criteria that are set for a welded connection, but without the need for “hot” work and the possiblity for installallation in Atex zone.

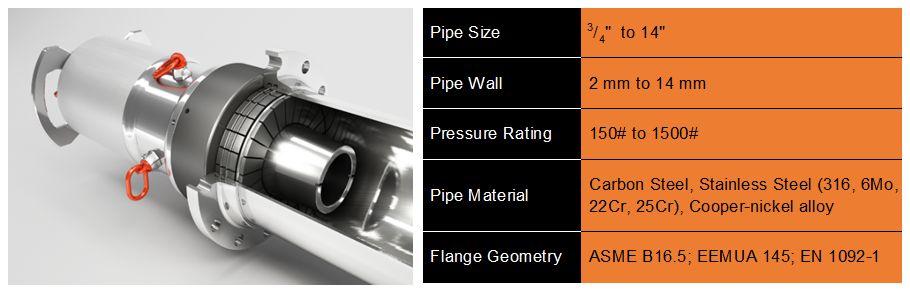

Quickflange™ patented technology provides a permanent gas tight and mechanically strong flange-to-pipe connection without welding. The installation is achieved by combining a modified standard flange with a hydraulic tool. The patented internal groove pattern is machined in such a way that it slides over the pipe end and is activated with a cold-forging tool. The two processes generate huge contact pressures, forming a seal and grip on the pipe. No spark or heat is generated and the process secures a metal to metal sela with no moving parts, balls, springs or gaskets.

More information about application and technical specifications of Quickflange™ technology can be found here.

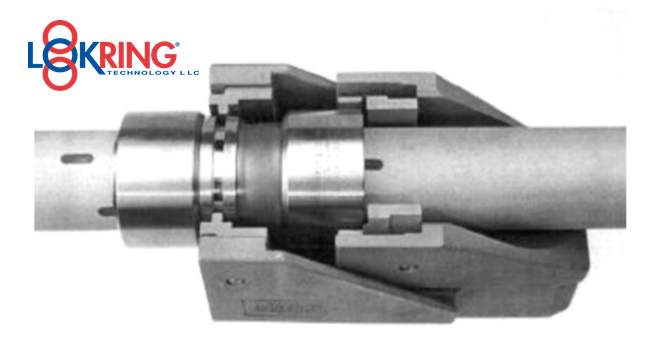

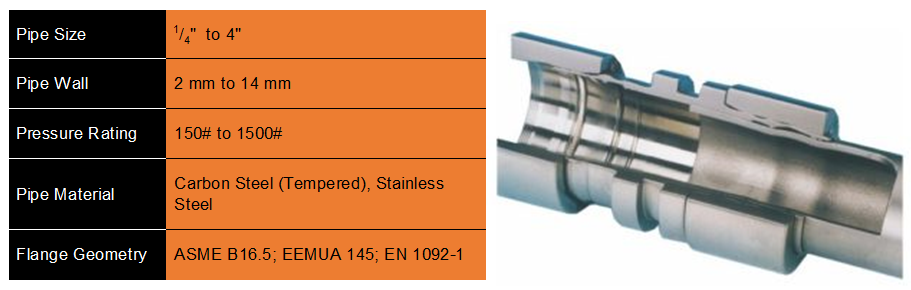

Lokring pipe fittings are the “cold” alternative to welding. During assembly, the clamping rings are hydraulically pressed over the fitting with specially designed tools. The sealing slats, which are located on the inside of the fitting, are pressed against and into the outer wall of the pipe.

More information about application and technical specifications of Lokring fittingen® can be found here.

Nederlands

Nederlands